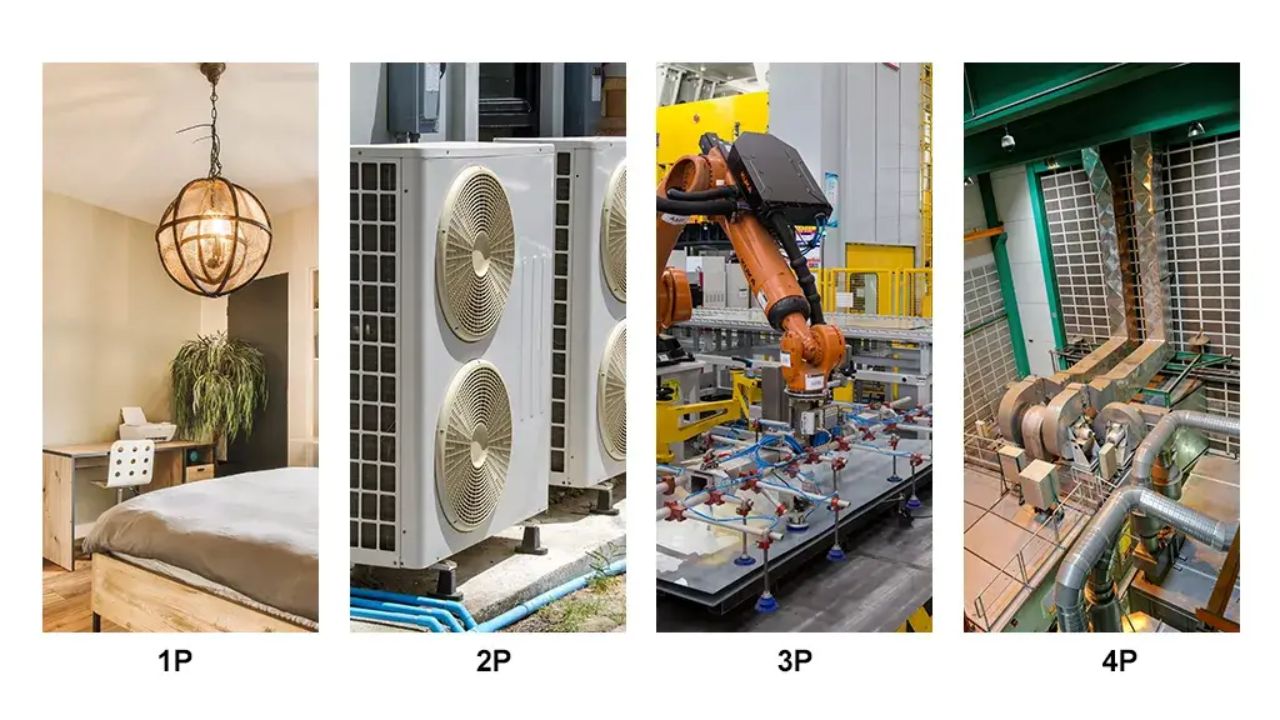

What Are Some Important Applications Of Aluminium Heatsink Extrusion?

For the efficient control of heat in a wide range of machinery and devices including electronic devices terminals and systems heat sinks are a crucial component. Understanding heat sinks can help you achieve effective heat removal allowing you to maintain the optimum operating temperature for your device.

A high-power heat sink and heat sink system are both typical of the aluminum extrusion heat sink. The Kingka Thermal Center can offer a dependable natural convection environment solution in accordance with the established mature technology of aluminum extrusion profile heat sinks.

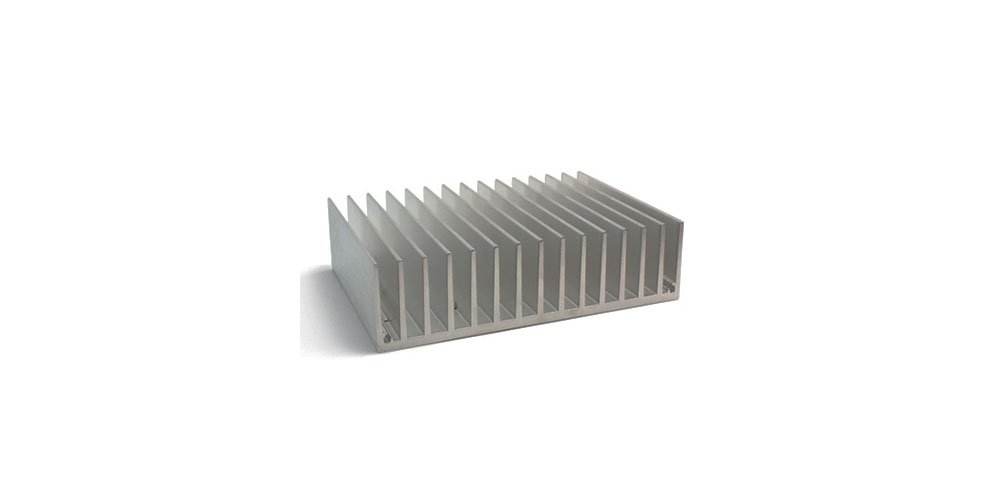

By extruding aluminum using a die the complicated structure of the heat sink can be achieved. The heat sink’s surface area is increased by these intricate fins, which also speed up the aluminum block manufacturing process and lower processing costs aluminium heatsink extrusion and its certain users will be discussed in this article.

Reason for Choosing Aluminium For Heat Sinks?

- Why was the aluminum profile chosen as the heat sink material? Because of its strong thermal conductivity aluminum is lightweight and has a good impact on energy savings.

- Due to the high cost of copper and the difficulty in processing them into attractive designs, copper heat sinks are not frequently used.

- Aluminum outperforms stainless steel in terms of heat dissipation and corrosion resistance. Aluminum is therefore the ideal material for a heat sink.

- The most economical options for the majority of electronic cooling applications are extruded aluminum heat sinks.

- Kingka provides a huge selection of aluminum profiles for making custom heat sinks and other things.

- Aluminum alloy 6063 which has a high performance and smooth surface is used by Kingka to extrude heat sink profiles.

- There are no NRE tooling charges or minimum order quantities. Per inch of extrusion length, the statistics on thermal performance are constant.

Positive Aspects of Aluminum Heatsink Extrusion

Resistance to Corrosion

The extruded aluminum heat sink has a long service life because of its high level of corrosion and rust resistance. This is one of the elements that affect how long the heat sink will last. It can tolerate greater temperatures for a significantly longer period of time because of its solid oxide construction and thick film-coated surface.

Economical

It has been proven that copper heat sinks are substantially better at dissipating heat than extruded aluminum heat sinks. Extruded aluminum heat sinks, on the other hand, are substantially more affordable to buy and produce.

Energy Saving

Due to the substantial amount of energy, it saves during production, aluminum is by far the most used heat sink material. Extruded aluminum heat sinks are more efficient than cast iron heat sinks at dissipating high temperatures, frequently by a factor of two.

Safe to Use

This specific type of heat sink has a unique resistance, especially when compared to those made of copper, iron, or steel. There is less chance of damaging it or making a mistake when it is handled or fitted because it can withstand tremendous pressure and impact. As a result, it is much safer to use, and the likelihood of accidents happening during fabrication or handling is greatly diminished.

Final Remarks

Extruded heat sinks can be produced with various types of welds, with unique fins tailored to the needs of the devices, and even in a variety of different colors and sizes. Due to all of the above-mentioned advantages, extruded aluminum heat sinks are perfect for use in mass production or manufacturing as well as for retail purchases.